5 Axis AM-CAM & Material Research Software

MiXO Pro

Perfect Solution for Simultaneous 5-Axis AM-CAM

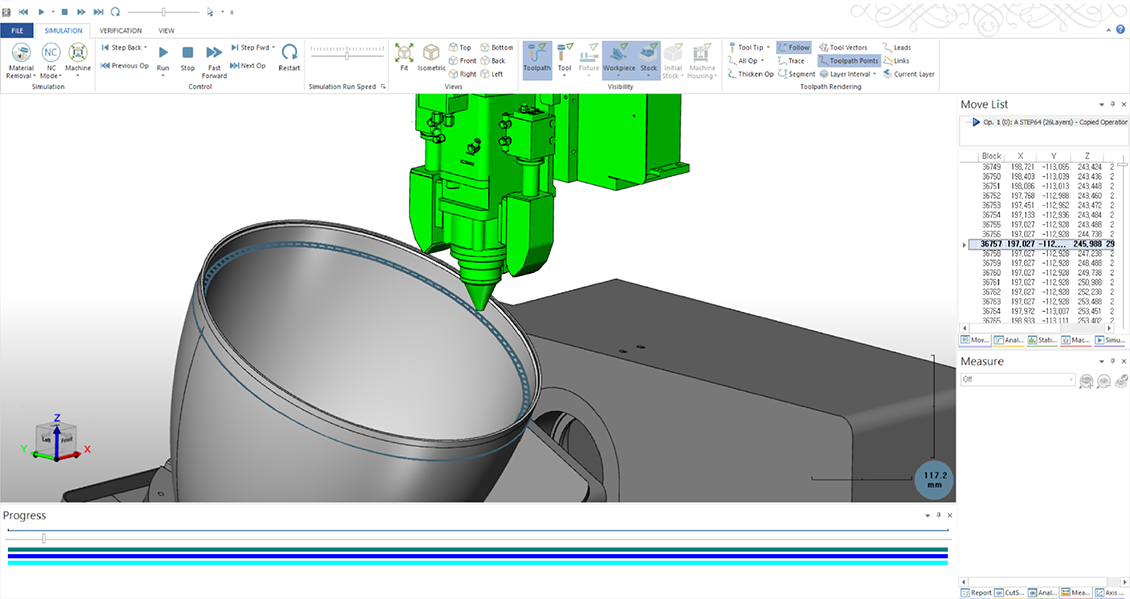

Simultaneous 5-Axis AM-CAM is one of the most important technology of InssTek's DED Additive Manufacturing. Combined with InssTek's years of know-how, MiXO Pro enables us to overcome the limitations of existing DED technology. We are breaking the limits of Additive Manufacturing.

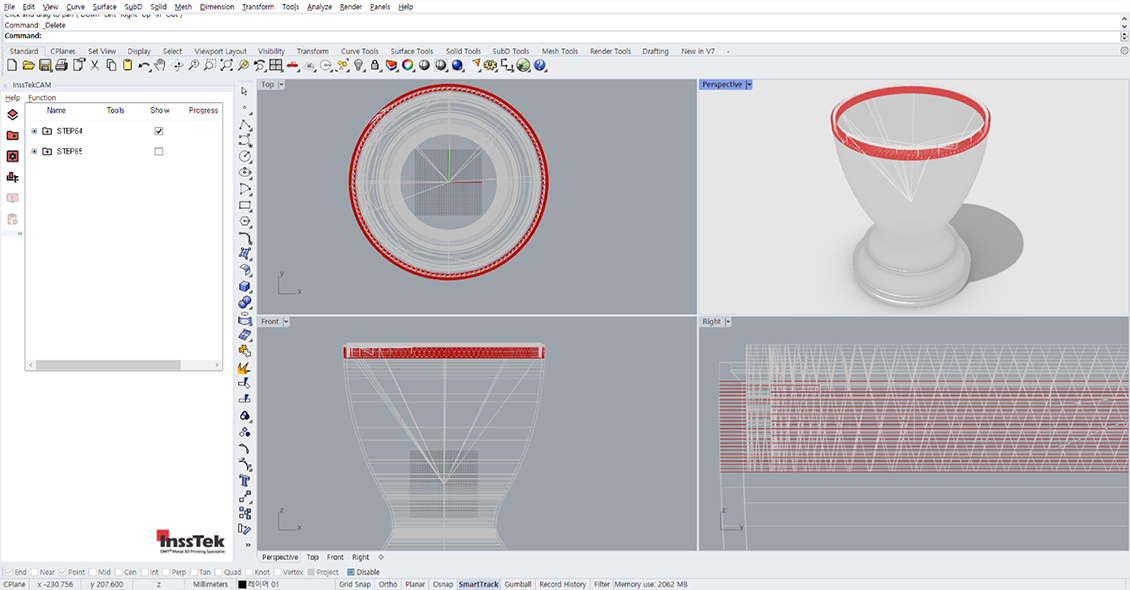

MiXO Pro for Tool Path Generation & Simulator

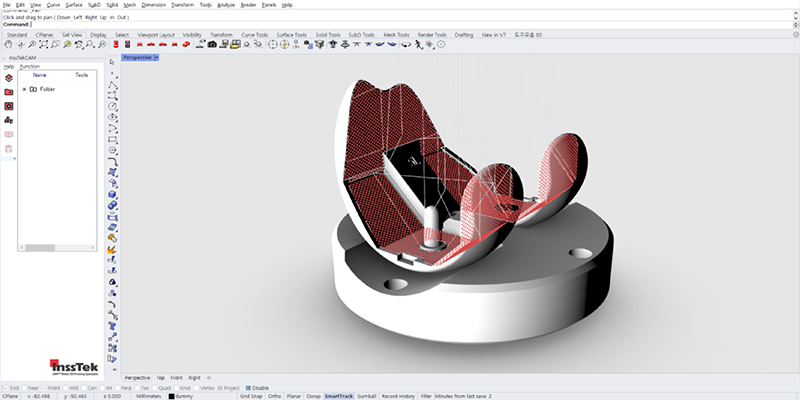

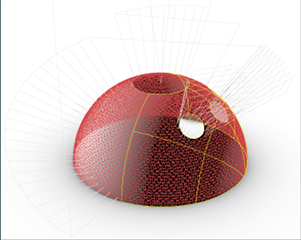

MiXO Pro for Metal Porous Coating

Simple porous coating procedure with simple steps and easily controllable pore shape, thickness, roughness

-

5-Axis CAM coating function is the key solution that can perform porous coating in various product lines such as artificial joints and semiconductor industry with DED print.

MiXO

Easy and simple 3-Axis program for Material Research

MiXO allows you to experience a variety of alloy designs that cover a wide range of research objectives in the field of materials science by exploring the infinite possibilities of material constitution methodologies and different geometries. These methodologies comprehend Matrix Material Composition (MMC), Functionally Graded Materials (FGM) and High Entropy Alloys (HEA), which with MiXO user-friendly interface. This software is compatible with all our machines and has been specially designed to support powder metallurgy and new alloys research through 3D printing applications.

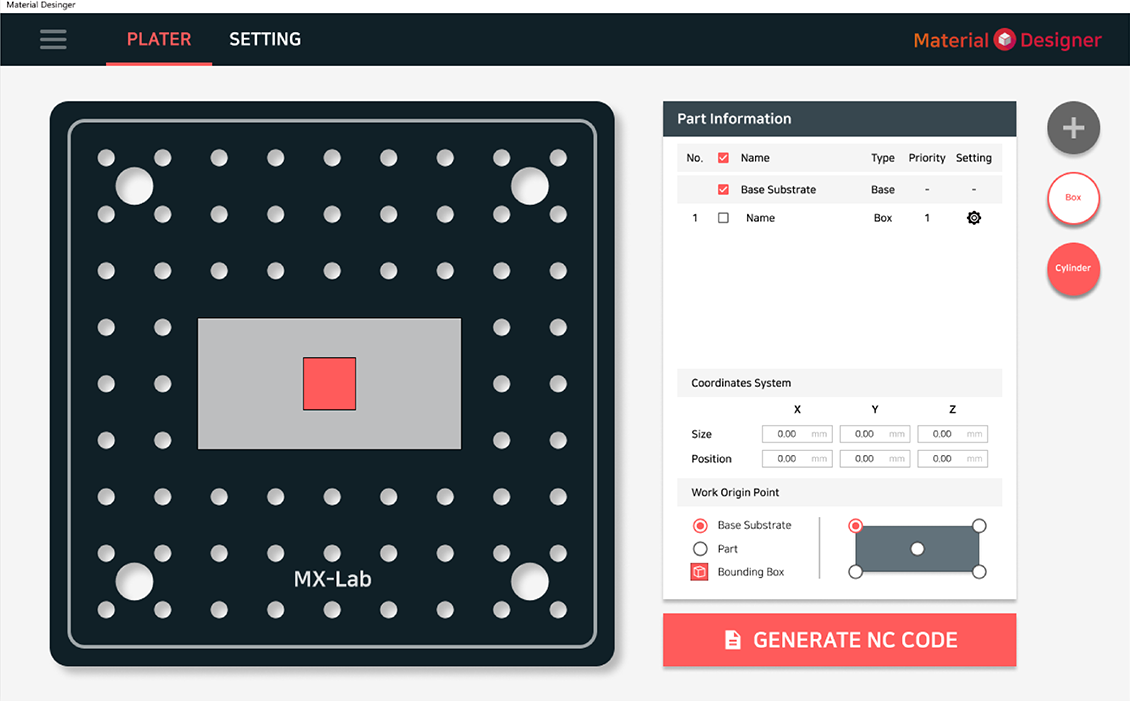

Material Designer

Easy and simple program for Material Research

Material Designer is a software that has been exclusively designed for MX-Lab. It rapidly creates rectangular and cylindrical geometries, and quickly generates NC Codes without the need of any 3D software. With Material Designer, experiencing a variety of alloy designs covering a wide range of research goals in the material science field is possible, by exploring the boundless possibilities of the diverse material configuration methodologies, naturally merged, and user friendly in the functionality of this software, Such methodologies are: Metal Matrix Composites (MMC), Functionally Graded Materials (FGM), and High Entropy Alloys (HEA).