Others | AMPM2021 Conference - NiCoMoTiAl High Entropy Alloying in DED/AM

page information

Writer InssTek 작성일21-06-21 18:30related link

-

https://www.mpif.org/Events/PowderMet2021/Program/TechnicalSession/Wed…

615 times connection

https://www.mpif.org/Events/PowderMet2021/Program/TechnicalSession/Wed…

615 times connection

-

https://www.linkedin.com/feed/update/urn:li:activity:68126300598878003…

1241 times connection

https://www.linkedin.com/feed/update/urn:li:activity:68126300598878003…

1241 times connection

body text

InssTek will be participating in the AMPM2021 conference on June 2021, hosted by Orlando, Florida.

▶Technical Sessions A22 : Alloy Design & Development

243 - NiCoMoTiAl High Entropy Alloying in DED/Additive Manufacturing Process:

Investigation the Potential of CVM Powder Feeding System for Rapid Alloy Scanning

(SeungJun An, Insstek, Inc.)

High Entropy Alloys(HEAs) is attracting attention as a new material to be used in various industrial fields with its excellent physical properties that can adapt to extreme environments.

Especially in aerospace and the energy industry, the requirementfor alloys maintainingproperties athigh temperature environments is increasing,and HEAs are being studied intensively to solve its.

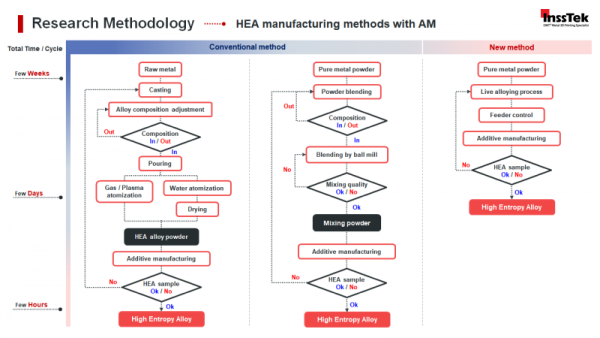

Each of the five elements comprising the alloy is manufactured from pure metal powders, with DED/AM technology in various combinations. This allowsthe rapid design of the proper portion of elements.

DED 3D printing with the multi hopper & clogged vibration method is a technology optimized for high entropy alloy research because it can speed-scan an alloy with various compositions at once.

The methods used in this experiment are expected to overcome the physical limitations of existing alloy design methods and present novel methodological paradigms of FGMs, MMCs, and HEAs studies.