Repair for Power plant applications: Turbine blade / Vane Repair using…

page information

Writer InssTek 작성일24-10-22 15:57related link

-

https://www.youtube.com/watch?v=mO0t6OxbYL8

285 times connection

https://www.youtube.com/watch?v=mO0t6OxbYL8

285 times connection

-

https://www.linkedin.com/posts/insstek_repair-powerplant-turbineblade-…

383 times connection

https://www.linkedin.com/posts/insstek_repair-powerplant-turbineblade-…

383 times connection

body text

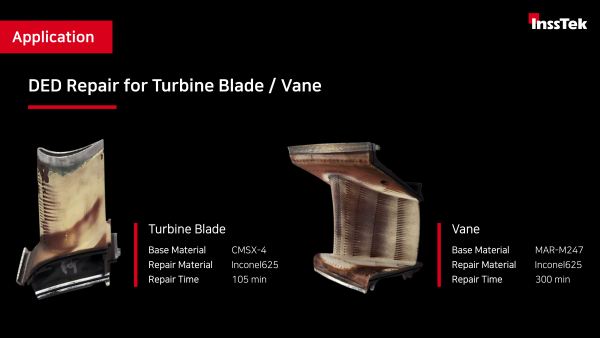

Repair for Power plant applications: Turbine blade / Vane Repair using Direct Energy Deposition

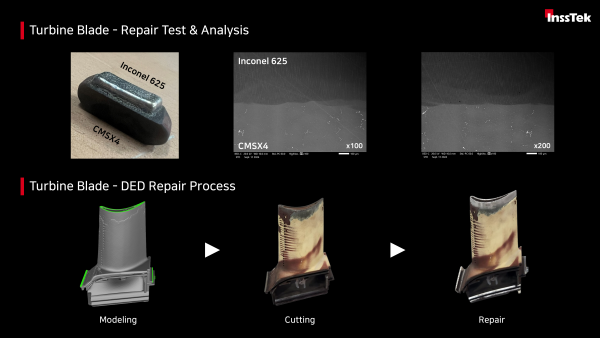

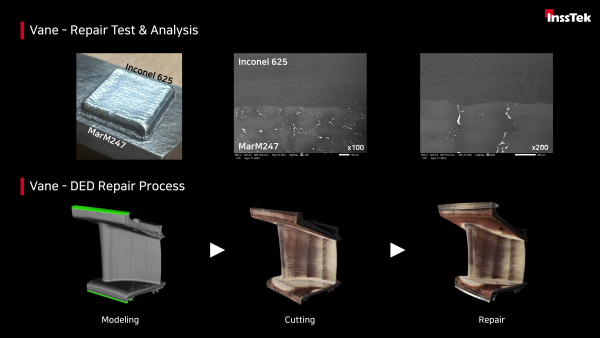

We have collaborated with GOD Tech to conduct DED (Direct Energy Deposition) repairs for power plant applications (Turbine Blade and Vane).

First, the damaged parts were simulated and then repaired through the DED process.

This method is economical, allowing users to continue using their equipment without the need to replace expensive parts with new ones.

[PART Information]

Turbine blade

- Base Material: CMSX-4

- Repair Material: Inconel625

- Repair Time: 105 min

Vane

- Base Material MAR-M247

- Repair Material: Inconel625

- Repair Time: 300 min

In this way, applying InssTek's DED process can not only print new parts, but also repair only the damaged parts of the existing components or apply other materials to the surface to give it new properties.

Video: https://www.youtube.com/watch?v=mO0t6OxbYL8

InssTek provides repair services for various parts using DED technology.

In addition, we have been consistently repairing Compressor blades and Jet engine air seals of aircraft engines.

You can check more cases from the link below.

https://insstek.com/application/repair

We have collaborated with GOD Tech to conduct DED (Direct Energy Deposition) repairs for power plant applications (Turbine Blade and Vane).

First, the damaged parts were simulated and then repaired through the DED process.

This method is economical, allowing users to continue using their equipment without the need to replace expensive parts with new ones.

[PART Information]

Turbine blade

- Base Material: CMSX-4

- Repair Material: Inconel625

- Repair Time: 105 min

Vane

- Base Material MAR-M247

- Repair Material: Inconel625

- Repair Time: 300 min

In this way, applying InssTek's DED process can not only print new parts, but also repair only the damaged parts of the existing components or apply other materials to the surface to give it new properties.

Video: https://www.youtube.com/watch?v=mO0t6OxbYL8

InssTek provides repair services for various parts using DED technology.

In addition, we have been consistently repairing Compressor blades and Jet engine air seals of aircraft engines.

You can check more cases from the link below.

https://insstek.com/application/repair

Comments list

No comments have been registered.