Home appliances

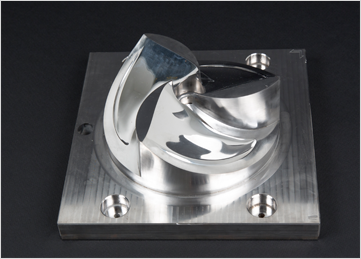

Cooling fan mold manufacturing by 3D conformal cooling channels

A global leading home appliances company had a noise issue on their refrigerators that caused by imbalanced cooling wings when it comes to injection. InssTek manufactured a cooling fan mold by 3D cooling conformal cooling channels method to enhance cooling efficiency and prevent unnecessary noise. Eccentric mass of the mold also enhanced.

Situation

- A leading home appliances company had a noise issue on their refrigerators that caused by imbalanced cooling wings when it comes to injection. Previously, cooling channels were only implemented in a straight line with low efficiency.

To solve with this issue, they engaged InssTek and asked us to develop 3D cooling channels for injection efficiency.

Solution

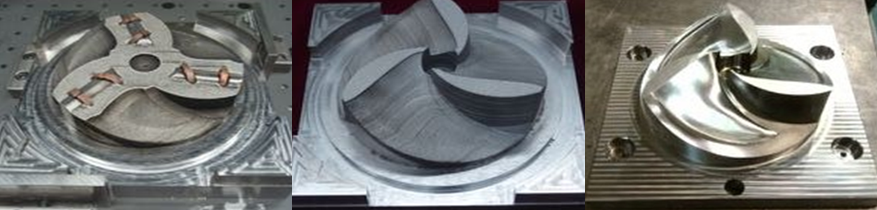

InssTek developed 3D printing cooling channels with the below phase:

- Inserting free-shaped cooling channels in mold core and finalizing it with the DMT technology

Advantages

Brought out cooling efficiency as well as preventing noise of refrigerators

- Enhanced Eccentric mass

- Previous: 0.33 gcm

- Current: 0.06 gcm