Microstructure and property enhancement of 7075 aluminium alloy via la…

page information

Writer InssTek 작성일24-01-22 17:31related link

-

https://www.linkedin.com/feed/update/urn:li:activity:71551137666935726…

377 times connection

https://www.linkedin.com/feed/update/urn:li:activity:71551137666935726…

377 times connection

body text

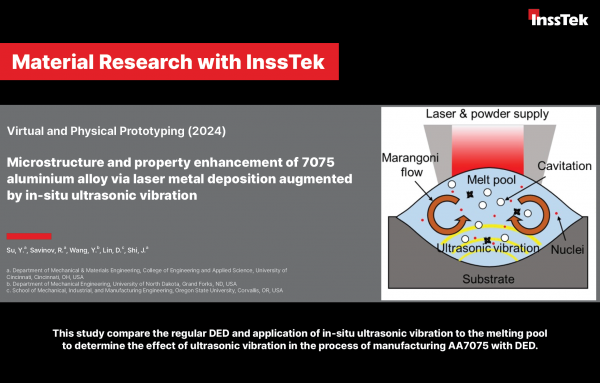

“Material Research with InssTek”

- Summary :

• This study compares the regular DED and the application of in-situ ultrasonic vibration to the melting pool to determine the effect of ultrasonic vibration in the process of manufacturing AA7075 with DED.

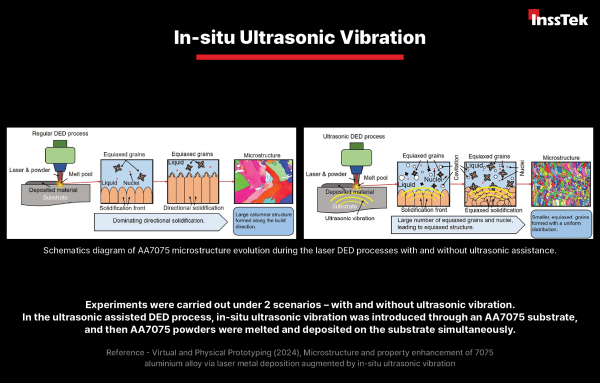

• Experiments were carried out under 2 scenarios – with and without ultrasonic vibration.

In the ultrasonic-assisted DED process, in-situ ultrasonic vibration was introduced through an AA7075 substrate, and then AA7075 powders were melted and deposited on the substrate simultaneously.

• The improved microstructure contributes to the development of superior mechanical properties.

Consequently, the integration of DED with ultrasonic vibration enhances the mechanical performance of AA7075 alloy.

Reference:

https://www.tandfonline.com/doi/full/10.1080/17452759.2023.2301482

- Summary :

• This study compares the regular DED and the application of in-situ ultrasonic vibration to the melting pool to determine the effect of ultrasonic vibration in the process of manufacturing AA7075 with DED.

• Experiments were carried out under 2 scenarios – with and without ultrasonic vibration.

In the ultrasonic-assisted DED process, in-situ ultrasonic vibration was introduced through an AA7075 substrate, and then AA7075 powders were melted and deposited on the substrate simultaneously.

• The improved microstructure contributes to the development of superior mechanical properties.

Consequently, the integration of DED with ultrasonic vibration enhances the mechanical performance of AA7075 alloy.

Reference:

https://www.tandfonline.com/doi/full/10.1080/17452759.2023.2301482

Comments list

No comments have been registered.