Deposition characterization of high-manganese (13Mn) steel built via d…

page information

Writer InssTek 작성일24-02-13 19:33related link

-

https://www.linkedin.com/feed/update/urn:li:activity:71627169703693434…

430 times connection

https://www.linkedin.com/feed/update/urn:li:activity:71627169703693434…

430 times connection

body text

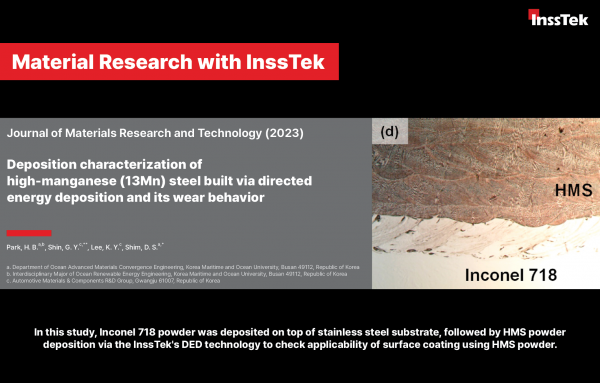

“Material Research with InssTek”

- Summary :

• In this study, Inconel 718 powder was deposited on top of a stainless steel substrate, followed by HMS powder deposition via InssTek's DED technology.

Through this, the industrial applicability of surface coating using HMS powder for maximizing wear resistance has been demonstrated.

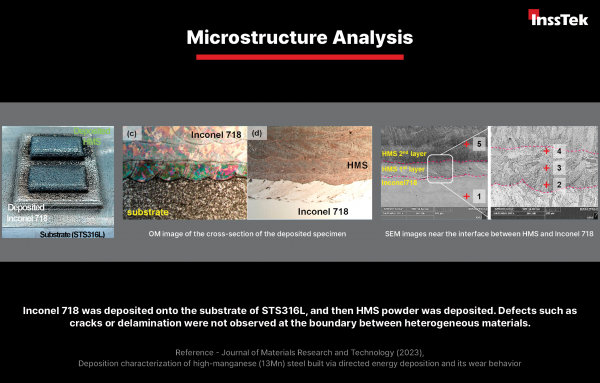

• Inconel 718 powder was deposited onto the substrate of STS316L, and then HMS powder was deposited according to different DED conditions.

Defects such as cracks or delamination were not observed at the boundary between heterogeneous materials.

• A wear test was conducted for the deposited HMS specimen, wear characteristics varied depending on load and RPM.

Based on these results, the most effective wear conditions for applying HMS coating could be identified.

- Summary :

• In this study, Inconel 718 powder was deposited on top of a stainless steel substrate, followed by HMS powder deposition via InssTek's DED technology.

Through this, the industrial applicability of surface coating using HMS powder for maximizing wear resistance has been demonstrated.

• Inconel 718 powder was deposited onto the substrate of STS316L, and then HMS powder was deposited according to different DED conditions.

Defects such as cracks or delamination were not observed at the boundary between heterogeneous materials.

• A wear test was conducted for the deposited HMS specimen, wear characteristics varied depending on load and RPM.

Based on these results, the most effective wear conditions for applying HMS coating could be identified.

Comments list

No comments have been registered.