Microstructural evolution and mechanical properties of functionally gr…

page information

Writer InssTek 작성일24-04-29 17:36related link

-

https://www.linkedin.com/feed/update/urn:li:activity:71906293856563240…

456 times connection

https://www.linkedin.com/feed/update/urn:li:activity:71906293856563240…

456 times connection

body text

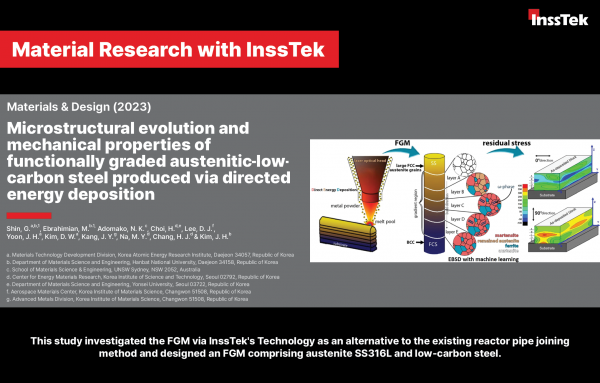

“Microstructural evolution and mechanical properties of functionally graded austenitic–low-carbon steel produced via directed energy deposition”

Highlights:

• This study investigated the FGM via InssTek's Technology as an alternative to the existing reactor pipe joining method and designed an FGM comprising austenite SS316L and low-carbon steel.

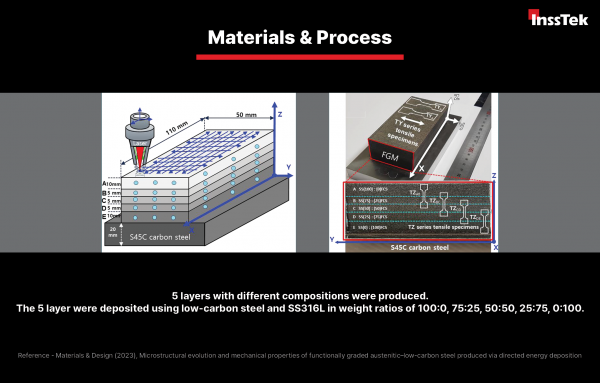

• 5 layers with different compositions were produced. The bottom layer was deposited using 100% low-carbon steel on an S45C carbon steel plate. The following 3 layers were deposited using low-carbon steel and SS316L in weight ratios of 75:25, 50:50, and 25:75. The top was deposited using 100% SS316L powder. Delamination and cracking didn’t occur.

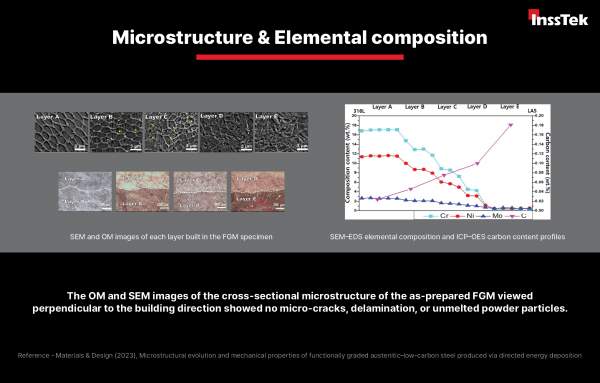

• The OM and SEM images of the cross-sectional microstructure of the as-prepared FGM viewed perpendicular to the building direction showed no micro-cracks, delamination, or unmelted powder particles. In addition, EDS analysis indicated that the composition of each layer was relatively uniform, and no major precipitation was observed.

Highlights:

• This study investigated the FGM via InssTek's Technology as an alternative to the existing reactor pipe joining method and designed an FGM comprising austenite SS316L and low-carbon steel.

• 5 layers with different compositions were produced. The bottom layer was deposited using 100% low-carbon steel on an S45C carbon steel plate. The following 3 layers were deposited using low-carbon steel and SS316L in weight ratios of 75:25, 50:50, and 25:75. The top was deposited using 100% SS316L powder. Delamination and cracking didn’t occur.

• The OM and SEM images of the cross-sectional microstructure of the as-prepared FGM viewed perpendicular to the building direction showed no micro-cracks, delamination, or unmelted powder particles. In addition, EDS analysis indicated that the composition of each layer was relatively uniform, and no major precipitation was observed.

Comments list

No comments have been registered.