2021 | InssTek's 3D printer was used to blend, dispense and melt two differen…

page information

Writer InssTek 작성일21-11-01 17:04related link

-

https://www.skoltech.ru/en/2021/10/magnetic-material-3d-printed-from-n…

444 times connection

https://www.skoltech.ru/en/2021/10/magnetic-material-3d-printed-from-n…

444 times connection

-

https://www.sciencedirect.com/science/article/abs/pii/S092401362100353…

556 times connection

https://www.sciencedirect.com/science/article/abs/pii/S092401362100353…

556 times connection

body text

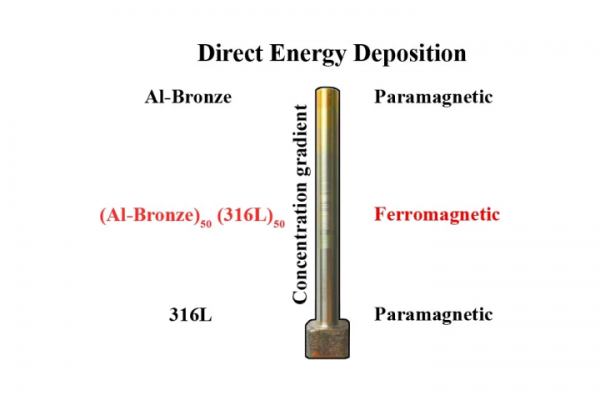

Utilizing an InssTek`s 3D printer, the researchers of Skoltech(the Russian Scientific and Technical Institute) were able to start out by dispensing a powder made of one metal, then gradually blending it with another metal powder until eventually only the other metal was being dispensed.

The magnetic properties of the metal rod continuously change from para- to ferromagnetic and back due to the shift in the relative proportions of the two constituent materials: marine-grade stainless steel (labeled 316L) and aluminum bronze (Al-Bronze).

However, when they were mixed together, an alloy was formed that exhibited soft ferromagnetic properties. This is an amazing achievement for highly efficient and suitable for manufacturing even large-size parts quickly and a way to discover new alloys.

[A paper on the research – which also involved scientists from Russia's St. Petersburg State Marine Technical University, National Research Center Kurchatov Institute, and Belgorod State University – was recently published in The Journal of Materials Processing Technology: Gradient soft magnetic materials produced by additive manufacturing from non-magnetic powders.]

The magnetic properties of the metal rod continuously change from para- to ferromagnetic and back due to the shift in the relative proportions of the two constituent materials: marine-grade stainless steel (labeled 316L) and aluminum bronze (Al-Bronze).

However, when they were mixed together, an alloy was formed that exhibited soft ferromagnetic properties. This is an amazing achievement for highly efficient and suitable for manufacturing even large-size parts quickly and a way to discover new alloys.

[A paper on the research – which also involved scientists from Russia's St. Petersburg State Marine Technical University, National Research Center Kurchatov Institute, and Belgorod State University – was recently published in The Journal of Materials Processing Technology: Gradient soft magnetic materials produced by additive manufacturing from non-magnetic powders.]