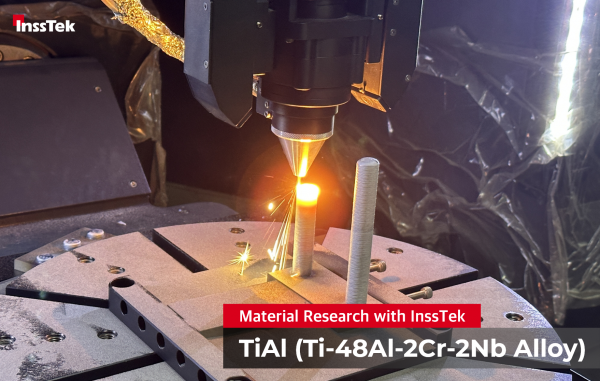

TiAl (Ti-48Al-2Cr-2Nb alloy) Deposition Test & Challenge

page information

Writer InssTek 작성일23-04-17 14:30related link

body text

TiAl (Ti-48Al-2Cr-2Nb alloy) Deposition Test & Challenge

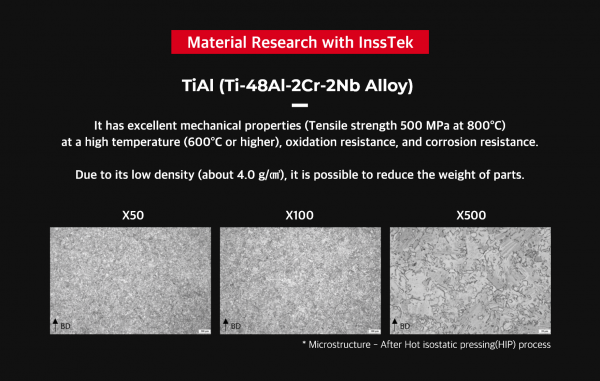

◇ Material (TiAl) Feature

- It has excellent mechanical properties (tensile strength 500 MPa at 800°C)at a high temperature (600°C or higher), oxidation resistance, and corrosion resistance.

- Due to its low density (about 4.0 g/㎤), it is possible to reduce the weight of parts.

- This material is used especially for power generation turbine blades, aviation LPT blades, and automotive turbocharger wheels.

◇ AM Research

We were able to identify crack-free microstructure through the Hot isostatic pressing (HIP) process. We will challenge complex shapes and huge sizes through the study of additive manufacturing processes.

◇ Material (TiAl) Feature

- It has excellent mechanical properties (tensile strength 500 MPa at 800°C)at a high temperature (600°C or higher), oxidation resistance, and corrosion resistance.

- Due to its low density (about 4.0 g/㎤), it is possible to reduce the weight of parts.

- This material is used especially for power generation turbine blades, aviation LPT blades, and automotive turbocharger wheels.

◇ AM Research

We were able to identify crack-free microstructure through the Hot isostatic pressing (HIP) process. We will challenge complex shapes and huge sizes through the study of additive manufacturing processes.

Comments list

No comments have been registered.